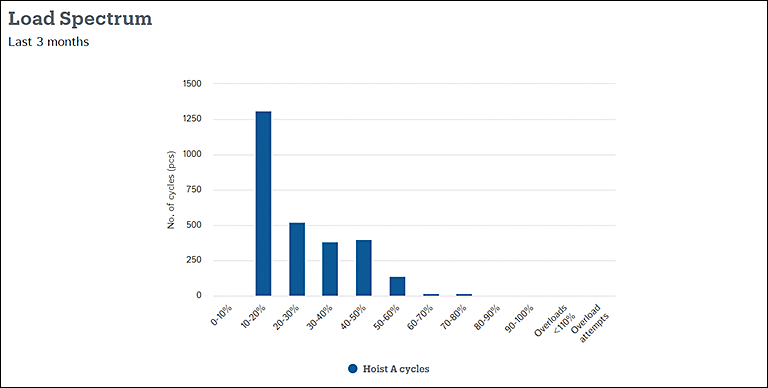

Load spectrum

The load spectrum shows how heady loads the hoist has been handling and reveals whether the hoist is in heavy or light use.

All loads that the hoist has handled are divided into load groups on the x-axis: 0%–10%, 10%– 20%, 20%–30%, and so on. A load group presents the weight of the load mass as a percentage of the hoist rated capacity. In practice, load group 0%–10% refers to operating the crane with an empty hook.

The y-axis presents the share of that load group among all hoisting cycles that the hoist has handled so far. In practice, one hoisting cycle corresponds to one lift with a load.

An overload occurrence is registered when the lifted load exceeds the rated capacity of the hoist by less than 10%. The condition monitoring unit allows the lifting motion to continue. An overload attempt occurs when the lifted load exceeds the rated capacity of the hoist by 10% for a certain time. At that point, the condition monitoring unit prevents the lifting motion.

The following can cause repeated overload attempts.

- Shock loading due to load balancing or jerking the load from the floor

- Load being side-pulled

- Operator error or misuse (unknown load weight, incorrect handling of below-the-hook devices)

- Overload protection device not properly calibrated

- Load not evenly shared with the hoists participating in the lifting operation

- Using one hoist to lift a load that has been intended to be lifted with two hoists

- Rated capacity of the hoist being insufficient for the load

- Improper rigging

You should then be concerned about cumulative fatigue or damage to various components, such as hooks, sheaves, wire ropes, rope drums, gear reducers, couplings, motors, and brakes. The recommended actions are as follows.

- Operator training to address rigging, crane controls, load swing, and pre-operational inspections

- Application study to determine whether the crane suits the current production and operating demands

- Crane reliability survey, critical component assessment, runway survey

If loads are at or in excess of 50%, increased attention to maintenance is required. Especially, if a hoist continuously lifts loads close to its maximum 100% level, its structures burden more and its service life shortens faster. By looking at the frequency of overloading and how often the load spectrum reaches the rated capacity, it is also possible to assess the suitability of the hoist for the current type of operation.