Motor condition

The Motor condition section concentrates on motor overtemperature occurrences and the possible causes behind them.

A motor overtemperature occurrence is registered each time when the hoisting motor stops because of overheating. The reasons include the following.

- Too many starts occur within a short timeframe

- Hoist is used above its duty class

- Hoisting motor is used above its design values (ED%)

- Two-speed motor is used excessively in slow speed

- Hoisting motor, fan, or filters are dusty

- Hoisting motor fan is damaged or the external fan is not operational

- Environment is hot or dirty

Overtemperature has a significant impact on the service life of the hoisting motor. Even one severe overtemperature occurrence can halve the service life. The recommended actions are as follows.

- Arrange operator training

- Check the motor design class

- Conduct an application study to determine whether the hoist suits the current production and operating demands

- Review the inspection and preventive maintenance schedule to ensure compliance with the instructions of the manufacturer

| NOTE | As motor overtemperature occurrences can result in the motor burning up, all such occurrences must be investigated. |

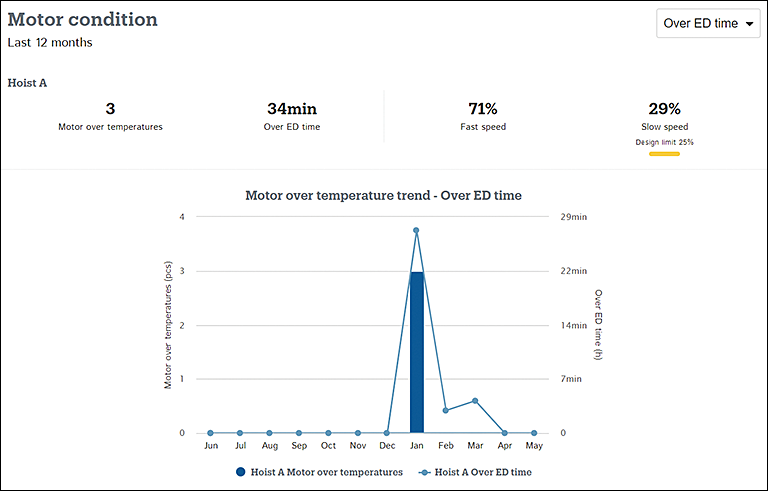

Above the graph, the following values are shown.

- Motor over temperatures: Total number of overtemperature occurrences in the hoisting motor.

- Over ED time: Total running time during which the hoisting motor has exceeded its rated ED, if any. Read more about ED below.

- Fast speed: Shown only for hoisting motors with 2-speed control. Percentage of the total running time in fast speed.

- Slow speed: Shown only for hoisting motors with 2-speed control. Percentage of the total running time in slow speed. As a general rule, slow-speed operation should not exceed 1/3 of total running time. If it does, a yellow bar appears under the slow-speed percentage, indicating an increased risk for motor overheating.

By default, the graph combines motor overtemperature data and over ED data. The vertical bars reflect the number of overtemperature occurrences in the hoisting motor. The scale for motor overtemperature occurrences is on the left. The trend line presents the over ED time, and it has its scale on the right.

Over ED is calculated based on the rated ED (from the German word “Einschaltdauer”) of the hoisting motor. Rated ED is a ratio of designed motor-on time to motor-off time. Rated ED reflects the time that the motor can be operated within a 10-min period, with or without load. For example, if the rated ED is 60%, the motor can be operated for 6 min during any 10-min period (60% of 10 min). The rest of the time the motor is supposed to cool down.

The over ED trend line reflects the total running time during which the hoisting motor has exceeded its rated ED, if any. Constant exceeding of the rated ED indicates that the hoist is being over-worked compared to its design. Such usage can lead to overheating, bearing wear, and stressing of all mechanical and electrical components in the motor. Solutions include the following.

- Inspect all motor components

- Shorten the service intervals of the hoist

- Upgrade to a hoist with a higher duty class

If the hoist has 2-speed control, you can switch your perspective between over ED data and fast/slow speed operation by using the drop-down menu top right. With the latter one selected, the trend line starts to reflect the percentage of slow-speed operation within total running time. The scale for motor overtemperature occurrences remains on the left, while the scale on the right switches to slow-speed time (%). Operating the hoist in slow speed for extensive periods of time increases the likelihood of overtemperature occurrences. By studying the graph, you may spot a cause-and-effect relationship between extensive slow-speed operation and overtemperatures.